TANKS

Oil tanks are an essential component of hydraulic systems, on which the system is extended. Therefore, their durability and reliability is very important, which we are able to guarantee. Twenty-five years of experience allows us to offer the customer design changes that increase the functionality of tanks and reduce the cost of its implementation.

- The tanks manufactured by KS Konstrukcje Stalowe are used in:

- machine industry (hydraulic power packs, hydraulic control systems),

- heavy industry (hydraulic presses, stamping presses),

- metallurgy (power systems for forging presses and manipulators),

- shipbuilding/maritime industry,

- heavy construction equipment (excavators, loaders, cranes, etc.),

- automotive - special vehicles,

- automation of production lines,

- vehicles used in agriculture (harvesters, agricultural machinery),

- mining industry, mining (roadheaders, mining vehicles, boring machines),

- power generation (conventional power plants, wind power plants),

- recycling equipment and lines,

- food industry (fruit presses and crushers),

- railways (lubrication systems, power supply of hydraulic systems).

Examples of projects:

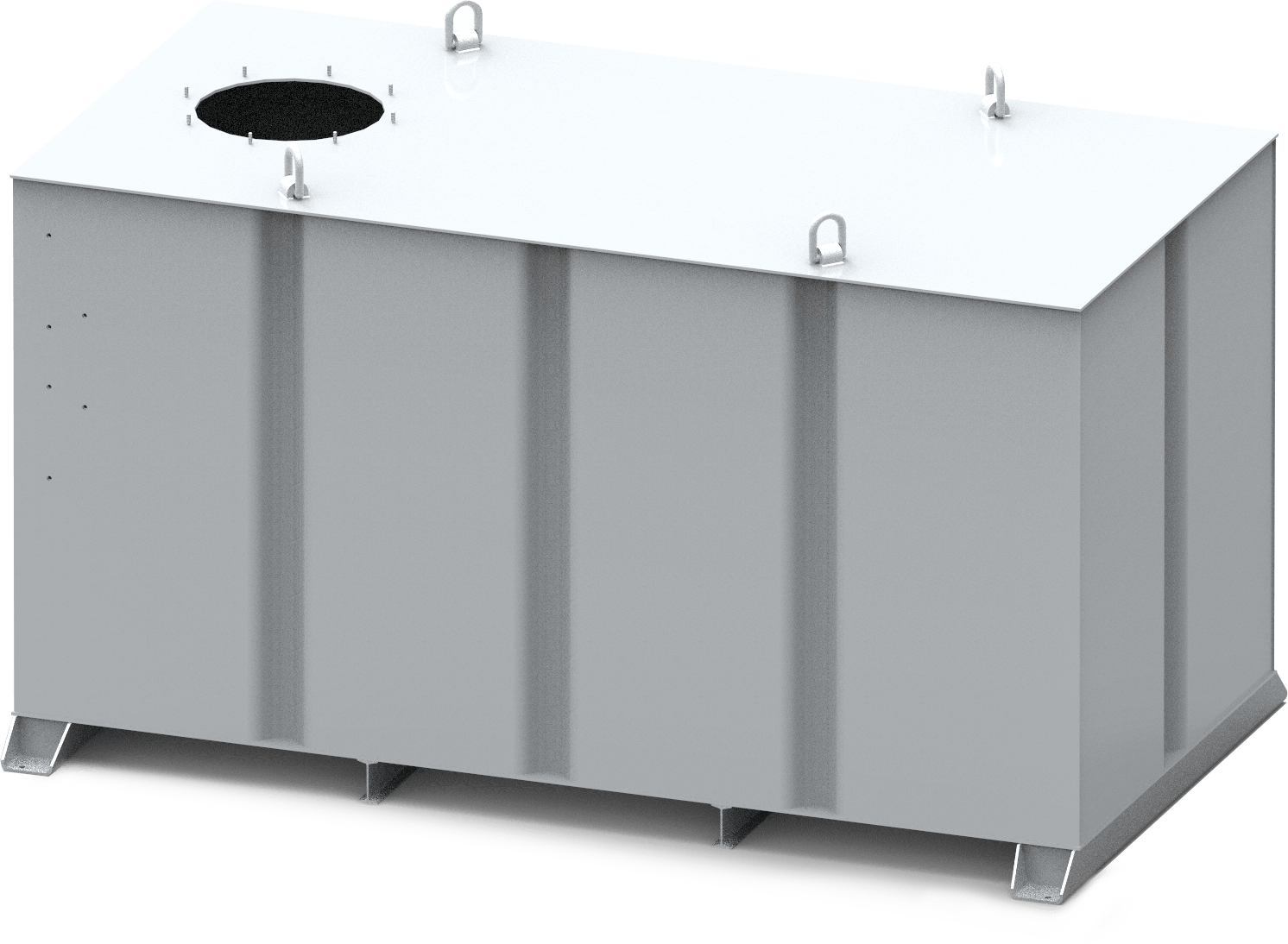

used for hydraulic power units

container with

a capacity of 630 litres

Basic types:

KBS tank:

capacity from 40 to 400 litres.

KBN tank:

capacity from 63 to 1250 litres.

KBE tank:

capacity from 12 to 300 litres.

KSB tank:

capacity from 2000 to 6000 litres.

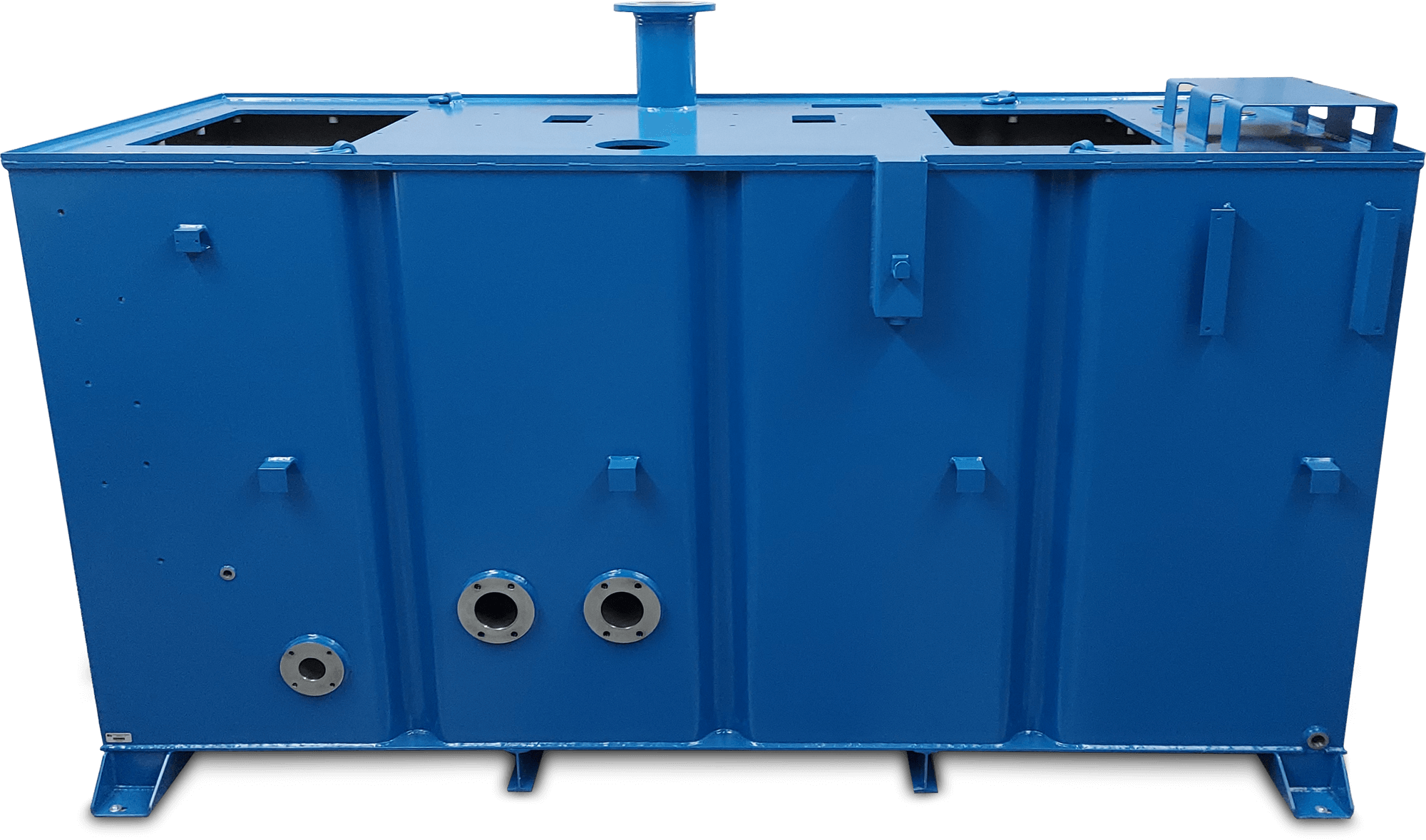

KSB 5000 tank

with modification.

KBE tank

with cover modification.

CARBON STEEL TANKS

The line of special tanks provides our customers with projects based on entrusted documentation, which completely differs from the design of catalogue tanks. Most often they are very individual constructions tailored to the place of destination and the needs of hydraulic systems. Past realizations range from 1 litre to 120,000 litres. Weight range from 2.5 kg to 30,000 kg. Carbon steel tanks and structures are available in many variants of corrosion protection.

Examples of projects:

STAINLESS STEEL TANKS

We also specialize in making tanks for power hydraulics systems, central lubrication systems and coolants made of stainless and acid-resistant steel (CrNi). After assembly, welding and cleaning in accordance with the customer's instructions, the tanks may undergo etching, passivation or glazing processes. Our projects of ferritic steel tanks range from 1 litre to 50,000 litres.

Examples of projects: